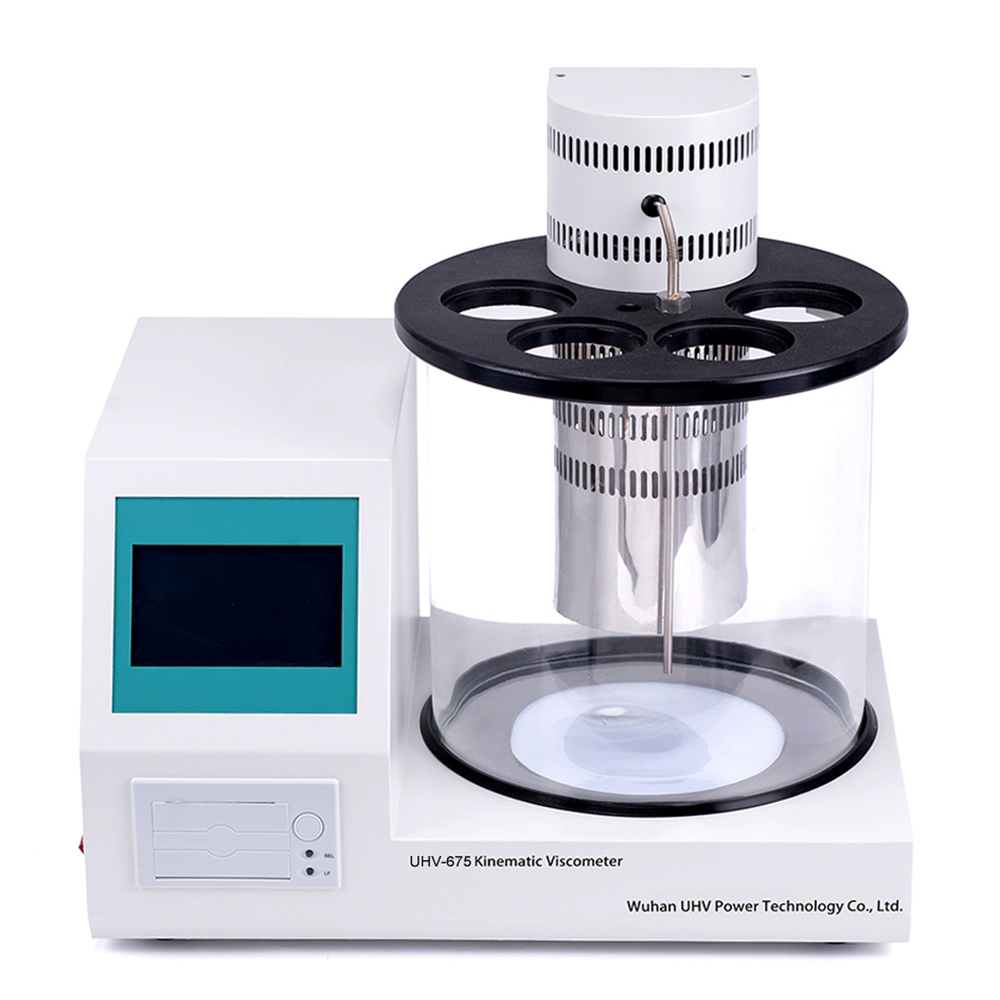

The kinematic viscosity tester under the UHV power company can help many power workers conduct various power tests more conveniently.

The influencing factors of the measurement results of the fully automatic kinematic viscosity tester

The fully automatic kinematic viscosity tester is based on a microcontroller. After setting a constant temperature point, the instrument automatically heats up, maintains a constant temperature, and turns on the stirring motor. When the temperature is constant, the experiment can be conducted according to the methods specified in GB/T standards.

Kinematic viscosity is an important indicator of lubricating oil. Kinematic viscosity is a conditional viscosity that measures the time it takes for a certain volume of liquid to flow through a calibrated glass capillary viscometer under gravity at a constant temperature. A friction surface with too low viscosity cannot form a firm oil film, which cannot guarantee reliable lubrication of engine components and will increase wear; On the contrary, it will make it difficult to start the engine, have poor low-temperature fluidity, increase wear, and reduce power. The accuracy of the measurement results of kinematic viscosity is influenced and constrained by various factors during the experimental process. The kinematic viscosity is often measured using a fully automatic kinematic viscosity tester, and its main influencing factors are as follows:

1. The temperature control of the constant temperature bath has a direct impact on the viscosity measurement results. As the temperature increases, the measurement results become lower; The temperature decreases and the viscosity measurement results are higher, so it is necessary to carefully control the test temperature to ensure that the temperature change is within the allowable tolerance requirement (± 0.1 ℃).

2. Suitable viscosity testers should be selected for the determination of different lubricating oils to ensure that the flow time of the lubricating oil in the capillary tube of the viscometer is not less than 200 seconds. When the flow time is less than 200 seconds, due to the fast flow velocity, the lubricating oil will flow in a turbulent state in the capillary tube, resulting in biased test results.

The verticality of instrument installation is another important factor affecting the measurement results. When the capillary tube of the viscometer tilts, the measurement results may become larger or smaller.

During the measurement process, the oil should also be kept clean and free of water.